Proven biomaterials and expertise for pioneering healthcare solutions

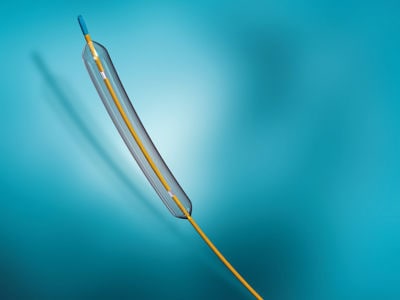

Every second of every day, a patient receives an implantable medical device featuring a biomaterial from DSM Biomedical. Our solutions and expertise support restorative healing, but they also support our many partners in a more efficient and sustainable way.

We are the biomaterials experts.

We work with partners worldwide across the continuum of healthcare to co-create innovative medical devices that bring progress to life for patients everywhere

150+

Years

150+ years of combined scientific discovery and heritage as part of dsm-firmenich

30+

Years

30+ years of experience working with the world’s leading medical device and pharmaceutical companies

25

25 FDA Material Master Files available to support regulatory submissions

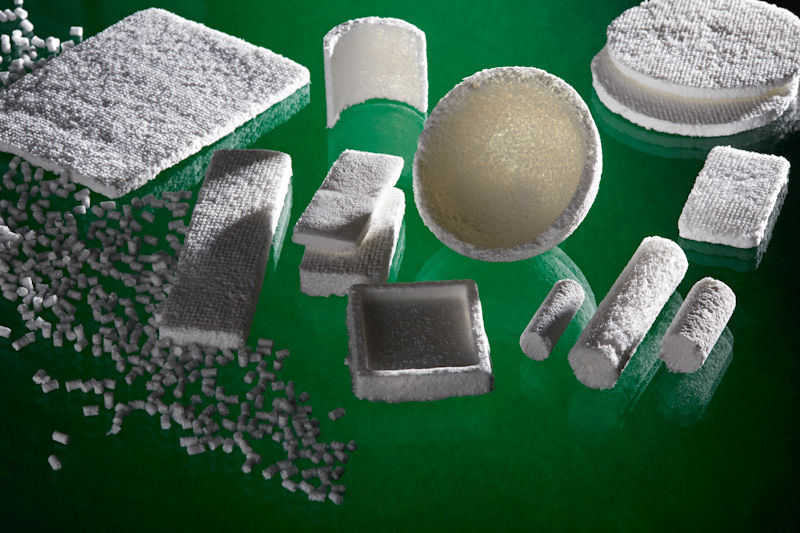

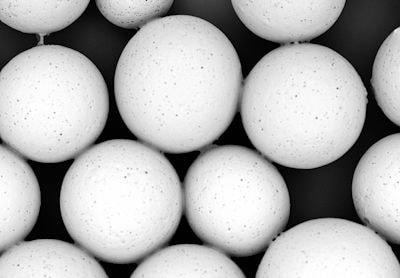

Our biomaterials solutions

The therapeutic areas that we serve

A long-term partner you can trust

We understand that medical product development can be a long, winding - and occasionally bumpy road. Rest assured that at DSM Biomedical, we have the proven experience, capabilities, and knowledge to support you every step of the way.

It starts with using a form-fit-function approach based on a comprehensive understanding of how the human body reacts to biomaterials following implantation. This in turn enables us to design materials that are compatible with the body’s physiology and help you develop finished products that can sustain, restore, and repair – all supported by applicable regulatory requirements.

Read more about our Certifications.

At our heart, we are a team that genuinely wants to change the future of medical care. Our biomaterials enable customers to create unique and specialized solutions that enhance doctors’ abilities to perform safer and more sustainable procedures that greatly improve patient outcomes. As one of the few companies capable of achieving this, our mantra is simple: ‘if not us then who?

John Witkowski, President, DSM Biomedical

Featured events

Connect with our team at upcoming industry events!

MD&M West, Booth #2855

FEB 6-8, Anaheim, CA

AAOS, Booth #2035

FEB 13-15, San Francisco, CA

ICI Meeting, Booth #17

FEB 25-27, Tel Aviv, Israel

CRS

JUL 8-12, Bologna, Italy

Want to learn more about DSM Biomedical?

Looking for technical resources & information?

SUSTAINABILITY

Bringing progress to life through sustainable biomaterials

We create sustainable healthcare solutions that deliver tangible and valuable sustainability benefits to our partners – with no compromises on safety or performance.