From science to solutions: supporting you across the continuum of healthcare

No matter where you are in your product development journey, we have the biomaterial technologies and expertise to put you on the path to success - and ensure that you stay on track. Across a wide range of therapeutic areas, we draw on 30 years of data, IP, and knowledge to help you create innovative healthcare solutions.

We work with partners worldwide across the continuum of healthcare to create innovative medical devices that bring progress to life for patients everywhere

150+

Years

150+ years of combined scientific discovery and heritage as part of dsm-firmenich.

30+

Years

30+ years of experience working with the world’s leading medical device and pharmaceutical companies.

25

25 FDA Material Master Files available to support regulatory submissions.

A long-term partner you can trust

No matter where you are in your product development journey, we have the proven materials, capabilities, and expertise to help make your vision a reality.

Innovation

Our approach to supporting your innovation is simple. Why reinvent the wheel?

We offer a wealth of scientific expertise and knowledge that extends beyond materials to how those materials can be applied - and combined - in new ways to add even greater value to your finished products.

This includes a combination of high-quality IP, clinical data, and FDA Master Files that enable our team to not only de-risk your research & development, but potentially accelerate it.

- Unrivaled scientific knowledge of biomaterials - based on our broad and diverse portfolio of technology platforms.

- 30+ years of expertise in how different biomaterial technologies can be combined and then customized to deliver targeted solutions.

- A unique consultative approach based on addressing your specific needs in a flexible and versatile way - and built on an extensive and ever-growing IP and data platform that our experts can apply from ideation to commercialization.

Quality Assurance & Regulatory Affairs (QARA)

Our QARA services bring peace of mind to your product development efforts while potentially accelerating time-to-market and avoiding potential roadblocks.

Our extensive quality system ensures that the biomaterials we produce are safe for use in the human body. Additionally, our regulatory team works closely with relevant external bodies to meet the stringent requirements needed for compliance worldwide. This includes:

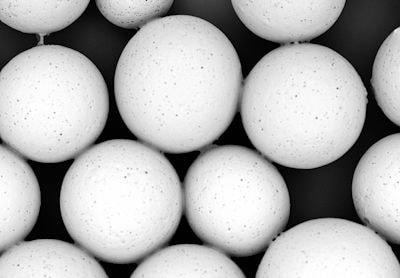

- ISO 1345 certification for the design, development, and manufacturing of biomedical polymers, speciality chemicals, bioresorbable implants fabricated alone or from combinations of synthetic resorbable polymers, bioceramics, and collagen.

- FDA Master Files on biomaterial technologies for use as part of your own regulatory submissions - thus saving valuable time and resources. This now includes our first Master File in China (for the use of polyethylenes).

- A commitment to best practices. We are regularly audited, and use these findings to further strengthen our quality systems.

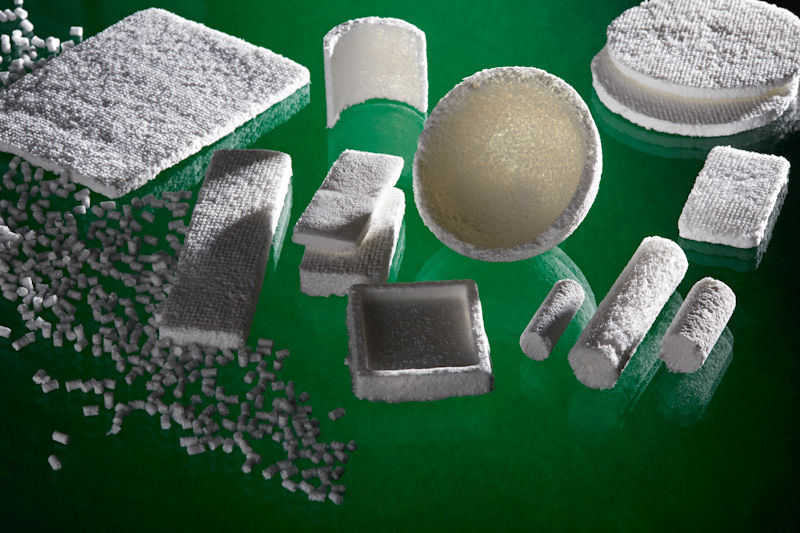

Specialized Biomaterials Manufacturing

Our Specialized Biomaterials Manufacturing (SBM) services are flexible, versatile, and always built on our extensive QARA capabilities, data sets, and IP.

We can support you in scaling up your commercial processes more efficiently through our strategic biomaterial manufacturing capabilities. In fact, our team can transfer entire product lines that we then deliver in a fully packaged and/or sterilized format. Our capabilities here include:

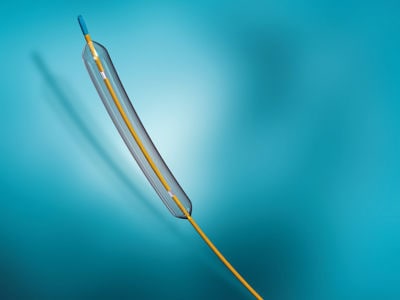

- We manufacture 3.5 million medical components annually from our FDA-certified facility - ranging from less than 50 pieces to over 40,000.

- This is complemented by a 30+ year track record in manufacturing and assembling medical devices (including various U.S. 510K clearances and CE mark approvals).

- From raw materials to fully packaged and sterilized final products, we support you every step of the way with our commercial expertise - all delivered in a turnkey format.

Our global biomaterials experts

Cheng Wei, Ph.D.

Senior Scientist

Albert Llenas

Global Director, Market Development

Kornelia Matloka, Ph.D. & Romy Reijans

Commercial & Technical Development, Associate Scientist

Shelley Si

Commercial Development Manager, China

Andre Martinez, Ph.D.

Senior Scientist

Ben Kibalo

Technical Service Manager, Natural Materials

DSM Biomedical: supporting you every step of the way

We understand that medical product development can be a long, winding - and occasionally bumpy road. Rest assured that at DSM Biomedical, we have the proven experience, capabilities, and knowledge to support you every step of the way.

It starts with using a form-fit-function approach based on a comprehensive understanding of how the human body reacts to biomaterials following implantation. This in turn enables us to design materials that are compatible with the body’s physiology and help you develop finished products that can sustain, restore, and repair – all supported by applicable regulatory requirements.

An invitation for innovation

Contact us today to discover how our team can support your product development journey with our range of services.