Ulteeva Purity™ fiber

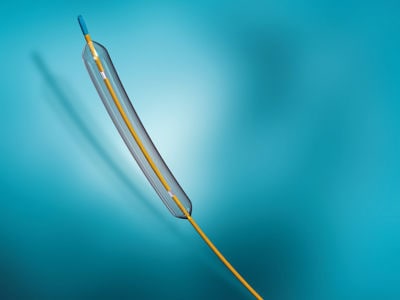

With its high strength at low-profile, our Ulteeva Purity™ fiber is considered the gold standard in UHMWPE solutions for a wide range of orthopedic, cardiovascular, and spine applications. It comes in a variety of high-contrast colors and densities and is ideal for use in suture, braid, cable, and textile constructs.