Premix Carriers

20 Jun 2022

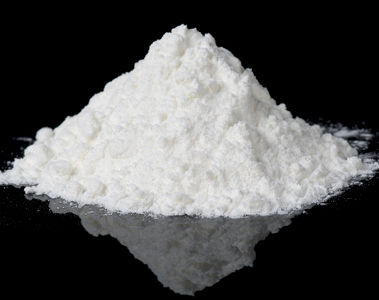

Premix carriers are much more than just a filler ingredient. Commonly the largest single component of a premix, carriers act as the glue that holds your nutritive ingredients in homogenous suspension, while also significantly influencing bulk density and flowability. From the many available options, choice of carrier must suit the final application, be it grain free pet food, water soluble, or conventional livestock feed, while also providing sufficient carrying capacity for the range of particle sizes of each nutrient. Read this article to learn more about the direct impact carrier type and proportions can have on premix quality.