High-performance hydrophilic coatings for long-lasting lubricity

Medical device companies rely on our hydrophilic coatings to bring new levels of functionality to vascular devices. Our ComfortCoat® family doesn’t just give you long-lasting lubricity and low particulate release; it’s also based on a universal chemistry that unlocks increased convenience and efficiency – and now includes a more sustainable solution.

We work with partners worldwide across the continuum of healthcare to create innovative medical devices that bring progress to life for patients everywhere

100+

Million

100 million+ devices coated each year.

15+

Years

15+ years of proven clinical history.

30+

Years

30+ years of experience working with the world’s leading medical device and pharmaceutical companies.

Why choose our hydrophilic coatings for your next project?

Our ComfortCoat® coatings are a safe and proven solution that deliver long-lasting lubricity and low particulate release – with a three-year shelf life. Furthermore, our hydrophilic coatings come ready-to-use with no mixing of components needed for fast, efficient, and reliable manufacturing.

This increased flexibility and versatility is further increased through our UV-curing technology which enables the fastest coating process in the industry – and is compatible with a wide range of polymer substrates and equipment. Complementing all of this, we bring you added peace of mind through:

- FDA Master File and documentation that support global regulatory filings.

- An established supply chain and robust ISO 13485 certified quality system.

- Secure supply, manufactured at a multi-ton scale.

Portfolio Overview

Discover our hydrophilic coatings solutions

- ComfortCoat® dual-layer lubricious hydrophilic coating

- ComfortCoat® single-layer lubricious hydrophilic coating

ComfortCoat® dual-layer lubricious hydrophilic coating

Ideal for vascular interventions, urology, and continence care applications, these coatings:

- Are based on a universal ready-to-use chemistry, compatible with a wide variety of devices and applications.

- Offer you a three-year shelf life: the longest in the industry.

ComfortCoat® single-layer lubricious hydrophilic coating

This single-layer coating gives you the same best-in-class performance and benefits as our dual-layer version - but with the potential to achieve significant operational efficiencies.

We achieve this via a UV curing process that uses biobased solvents to deliver tangible and valuable sustainability benefits – with no compromises on safety or performance.

Application spotlight: Taking your coatings further

What really differentiates DSM Biomedical is our ability to draw on an incredibly broad and versatile technology platform to meet your needs.

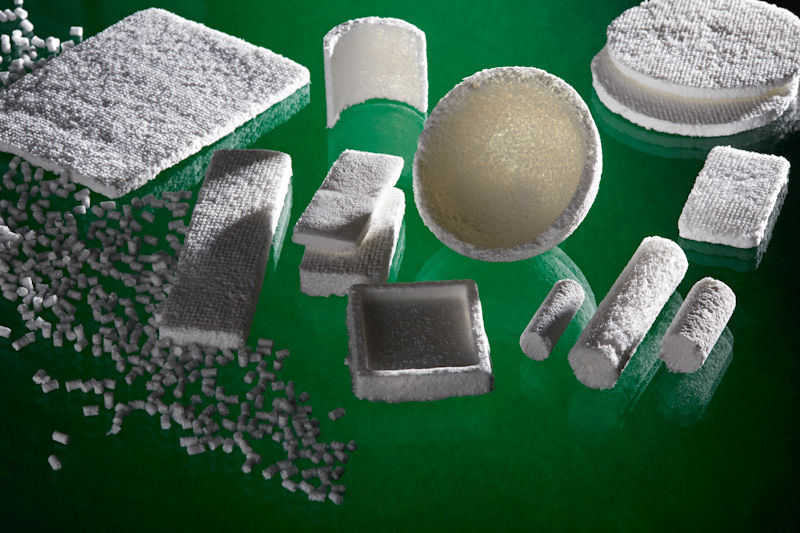

For example, our team can develop tailored medical coatings that that can be customized and combined with other biomaterials in our portfolio to deliver unique performance benefits: from collagen and polyester amides to polyurethanes and bioceramics.

We achieve this through a deep understanding of the product development process. For example, our ComfortCoat® hydrophilic material is based on a universal chemistry that makes it ready-to-use, with no mixing needed. Therefore, you can use this medical coating for a wide variety of medical devices – reducing chemical inventory while increasing operational efficiency.

Frequently Asked Questions

Here are common questions that our experts get asked. If you have a different question, please contact us.

What substrates are ComfortCoat® hydrophilic coatings compatible with?

These hydrophilic coatings are universally compatible with a wide range of polymeric substrates used in the industry, including: Pebax, Nylon, Peek, HDPE, PVC (solutions for metal and silicone are under development).

Does DSM Biomedical manufacture medical devices?

We are advanced biomaterials experts, with in-depth knowledge of medical device coatings and product development. However, we are not a medical device manufacturer and have no aspiration to become one.

How long do your hydrophilic coatings last? For example, what is the shelf life of the liquid formulation?

Three years (the longest in the industry) – ready-to-use/premixed.

How does the ComfortCoat® lubricious coating differ from the competition?

This top-performing medical coating product family is ready-to-use, universal (same chemistry/lean inventory) across different substrates and coating formulations. It also has a three-year shelf life and is manufactured at multi-ton scale. Ultimately, ComfortCoat® is the most efficient and convenient coating application process in the industry – and is supported by an unrivaled platform of biomaterial technologies and expertise covering many competences and clinical areas. For medical device companies everywhere, we are a proven partner, not a competitor.

What applications are your medical coatings used in?

Broadly, in coronary, structural heart, peripheral vascular, and neurovascular interventions; as well as urology and continence care. Specific applications cover a broad range of catheters including but are not limited to:

- Introducer sheaths

- Guidewires

- Access systems

- Guiding catheters

- Visualization catheters

- Microcatheters

- Diagnostic catheters

- Balloon catheters

- Thrombectomy devices

- Aspiration catheters

- Neurovascular catheters

- Stent delivery systems

- Stent graft delivery systems

- Heart valve delivery systems

- Foley catheters

- Intermittent catheters

Technical Resources

Download more information on how our hydrophilic coating technology and expertise can tackle unmet needs.

ComfortCoat®: Lubricious Hydrophilic Coating Datasheet

ComfortCoat® SL: Sustainable Hydrophilic Coating Brochure

We understand that medical product development can be a long, winding - and occasionally bumpy road. Rest assured that at DSM Biomedical, we have the proven experience, capabilities, and knowledge to support you every step of the way.

It starts with using a form-fit-function approach based on a comprehensive understanding of how the human body reacts to biomaterials following implantation. This in turn enables us to design materials that are compatible with the body’s physiology and help you develop finished products that can sustain, restore, and repair – all supported by applicable regulatory requirements.

Our expert biomaterials team is ready to support you

Discover how we can partner with you to co-create innovative solutions with our hydrophilic coatings portfolio.

Need expert assistance?

Our hydrophilic coatings experts are here to help.